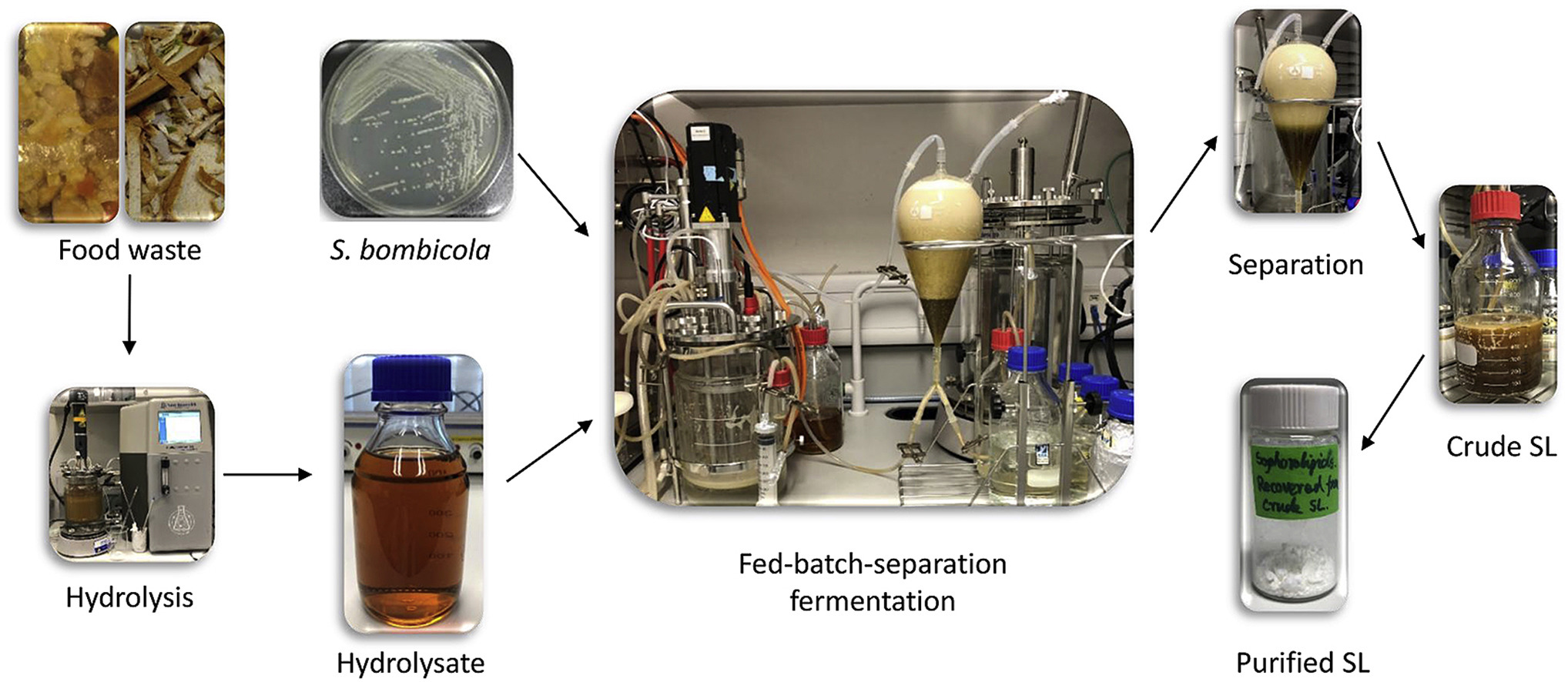

Until now, the production of microbial biosurfactants has been limited to the use of first-generation (food) substrates. Moreover, the results on sophorolipids yield and productivity reported by state-of-the-art fed-batch processes for sophorolipids production remain unsatisfactory and lead to a significantly high cost per kg of the product. With an aim to address these problems, this study demonstrates a long-term and high-efficiency sophorolipids production method using a semi-continuous integrated production-separation system which utilizes food waste as a substrate. An average volumetric productivity of 2.43 g L−1 h −1 and the overall sophorolipids yield on the substrate (i.e. the combination of glucose and oleic acid as carbon source) of 0.73 g g−1 was achieved within 240 h by fed-batch and separation fermentation.

You can find the full article right here.