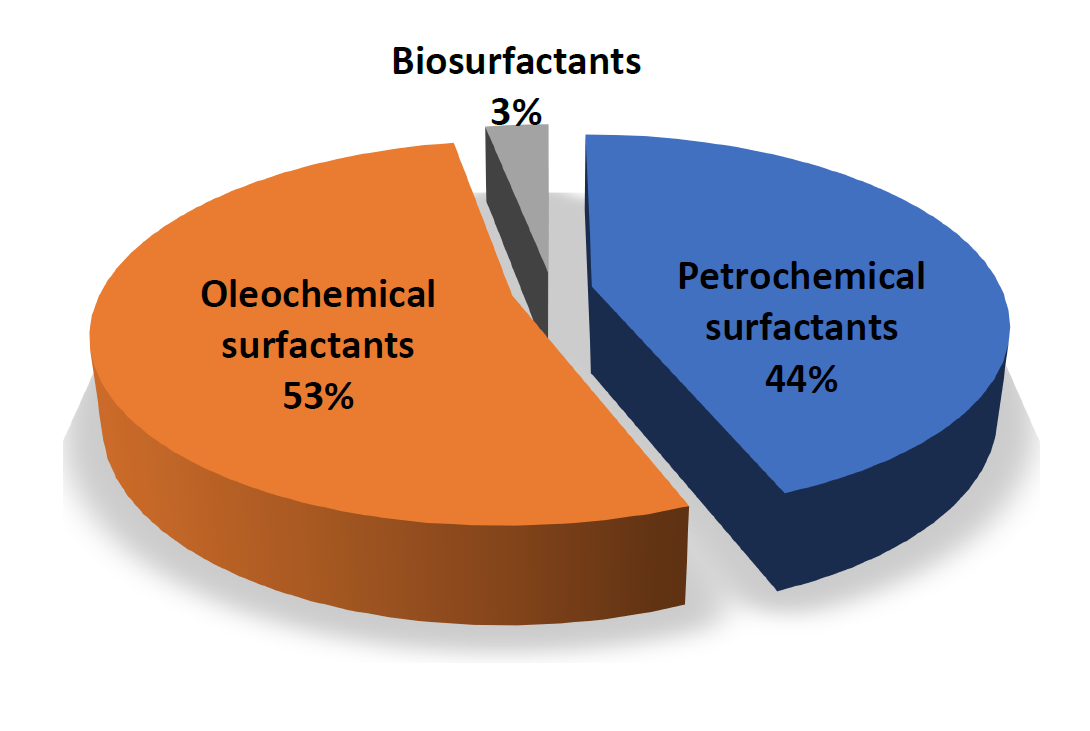

Surfactants find application in almost every aspect of modern daily life as they are widely used in drug formulation, cosmetics, cleaning agents, food, feed, agrochemicals, paints, etc. Historically, surfactants were produced in bulk from petrochemical resources. However, growing environmental awareness has caused a shift towards the so-called oleochemicals, which are partly derived from plant oils instead of crude oil, and are currently representing more than half of the surfactant market, as shown in the figure below. It has to be noted that these oleochemicals are only partly renewable and chemical production processes are applied for their production. A very small part of the surfactant market is represented by the so called ‘biosurfactants’, which are fully biobased surfactants. Approximately 5 % of these biosurfactants are microbial surfactants. The latter are produced through biological processes by organisms like yeasts and bacteria from renewable resources like plant oil, sugars and even waste streams. These interesting features, in combination with their low ecotoxicity profile and versatile application potential makes them worthy environmentally friendly alternatives.

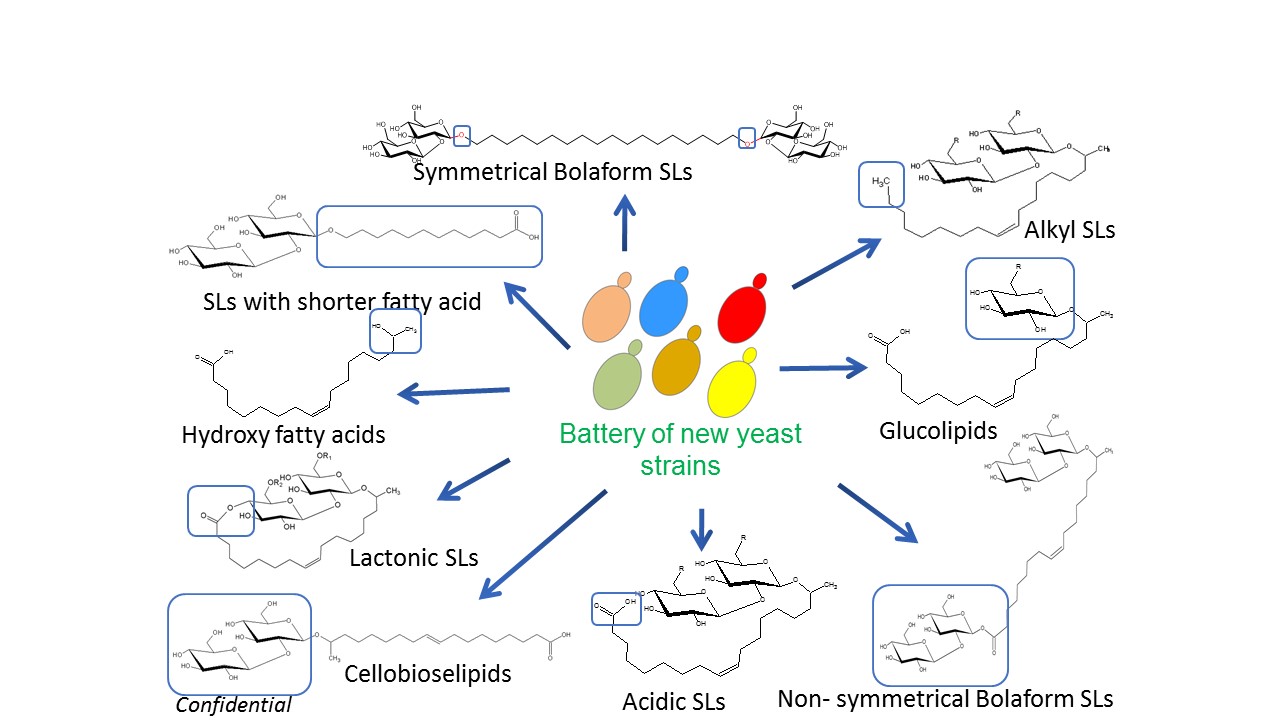

InBio.be took a pioneering role in domesticating one of the workhorses of glycolipid biosurfactants production, i.e. the sophorolipid producing yeast Starmerella bombicola, which is already used for industrial sophorolipid production. After years of molecular tool development, ‘-omic analyses’, genetic and metabolic engineering, this yeast was transformed into a production platform organism for (new-to-nature) biosurfactants and glycolipids. The present versatile portfolio of molecular structures which can be produced with our domesticated host is represented in the figure below.

Subsequent bioprocess development and scale up (at the Bio Base Europe Pilot Plant) enabled the development and optimization of economically feasible processes and, moreover to generate kg scale ‘samples’ of these new interesting molecules. Currently, state-of-the-art application research in a range of sectors is being conducted to identify and valorise the application potential of this technology platform. These molecules are expected to expand the market share of microbial biosurfactants soon.

An integrated process design approach developed at InBio.be (genetic engineering ⇔ process development ⇔ application research) is constantly further applied on new promising strains entering the innovation chain and several promising new leads are in the product pipeline.

For more information about biosurfactants and possible collaborations, please contact Prof. Wim Soetaert or Dr. Sophie Roelants.