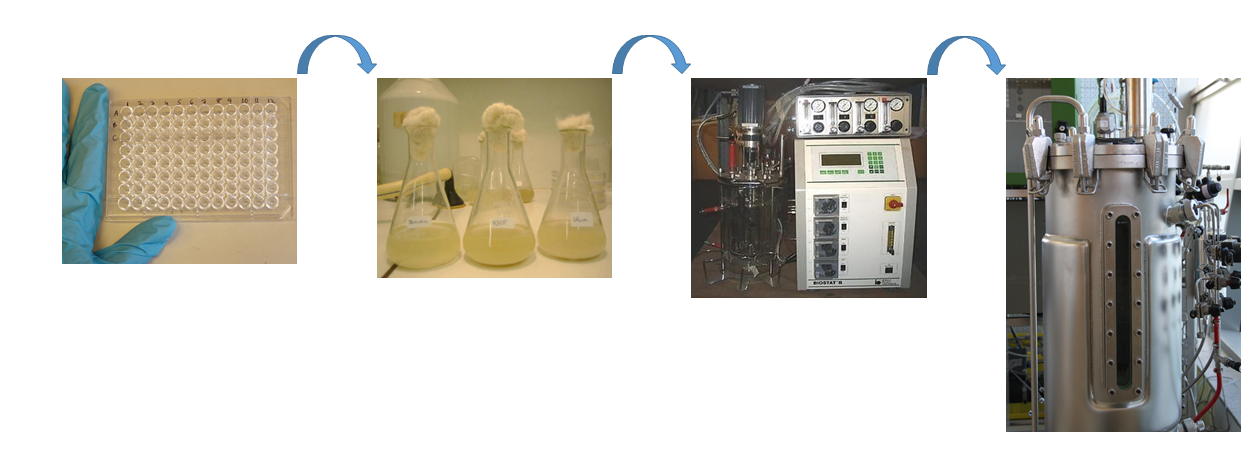

Target molecules, industrially valuable and/or new-to-nature, can be part of the intracellular or extracellular space, be water-soluble or insoluble, crystalline or amorphous, … and thus require the development of dedicated production processes i.e. fermentation and purification processes.

At InBio.be, a dedicated fermentor lab enables initial process development (feeding strategies, fermentation parameters, reactor set up, etc.) and subsequent scale up of the production process. The lab is equipped with laboratory and pilot fermentors (2L-100 L working volume) with full process control equipment and data acquisition software. InBio.be also has state-of-the-art analytical equipment involving HPLC, HPAEC ion chromatography, UPLC, and LC/MS-MS equipment for the analysis of metabolites. Finally, initial downstream processing development can be performed. Once a bioprocess is well defined, it can be further scaled up and optimized at the facilities of one of InBio’s key partners i.e. the Bio Base Europe Pilot Plant in the port of Ghent. Further downstream processing development is also performed at the Bio Base Europe Pilot Plant.

Available reactors at InBio.be:

Available reactors at InBio.be:

- 4 x 3L bioreactor

- 2 x 5L bioreactor

- 2 x 8 L bioreactor

- 1 x 30 L bioreactor

- 1 x 100 L bioreactor

For more details or if you are interested in a cooperation, please contact us.