Natural Product Discovery at InBio.be

Microorganisms, though invisible to the naked eye, are the true masters of our planet. Their remarkable ability to adapt and compete in diverse environments drives them to create an astonishing array of chemical compounds. These natural products—produced as part of their regular metabolic activities—often possess unique biological activities that hold immense potential for applications in medicine, agriculture, food, and industry.

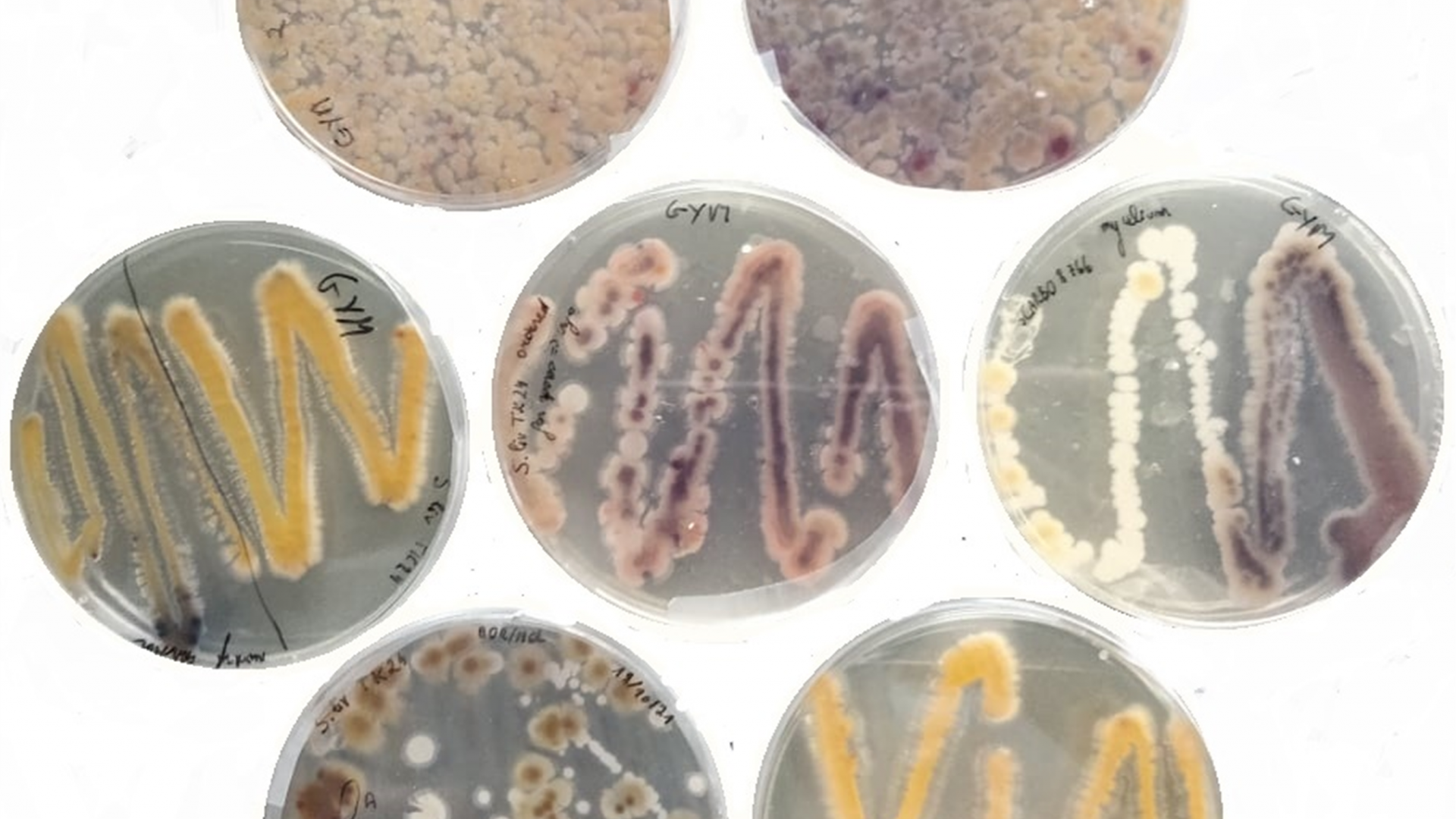

At InBio.be, our mission is to harness the untapped potential of these microbial metabolisms by exploring the vast diversity of microorganisms. This allows us to unlock a treasure trove of novel compounds that could lead to breakthroughs in drug discovery, biopesticides, food additives, and other innovations that benefit society.

A multidisciplinary approach

Natural product discovery is a vibrant, interdisciplinary field that bridges several scientific domains. Our research integrates expertise from multiple areas:

- Microbiology: understanding microorganisms—bacteria, fungi, and other microscopic life forms—at both cellular and community levels. By applying genome mining techniques, we uncover biosynthesis pathways encoded in the DNA through gene clusters that are rich sources of natural products.

- Natural Products Chemistry: utilizing advanced tools like spectroscopy, chromatography, and mass spectrometry, we delve into the chemical structures of natural products, leading to their identification and characterization (metabolomics).

- Molecular Biology: Investigating the genes and molecular regulatory mechanisms behind the production of natural products. Techniques such as gene cloning and expression help us decode the biosynthetic pathways, allowing us to engineer or optimize production.

- Biotechnology: transforming microorganisms into microbial cell factories enables us to produce valuable natural products and biomolecules in a more domesticated microorganism. This also includes optimizing bioprocesses, scaling up production, and developing efficient downstream purification methods.

- Pharmacology: assessing the biological activities of natural products, particularly their pharmacological and therapeutic potentials, as well as their ability to interact with biological systems to develop new medicines.

Application studies in conjunction with natural product discovery is what we aim for!

Beyond the lab: exploring natural microbial diversity with metagenomics

At InBio.be, we go beyond studying microorganisms in the lab. We explore microbial communities in their natural environments using metagenomics—a cutting-edge approach that reveals the diversity and complexity of uncultured microorganisms. Thanks to advances in high-throughput DNA sequencing, metagenomics allows us to discover new microbes, genes, and bioactive compounds faster and more affordably than ever before.

This powerful technique not only accelerates natural product discovery but also sheds light on the human microbiome, environmental ecosystems, and the roles microorganisms play in health, disease, and environmental processes. By uncovering these hidden microbial treasures, we gain deeper insights into the microbial world’s profound impact on life on Earth.

At InBio.be, we are driven by the potential of these discoveries to lead to innovative solutions with global benefits—whether in medicine, agriculture, or sustainable technologies.

For more information about HMOs and possible collaborations, please contact Prof. Wim Soetaert or Dr. Maarten De Mol.