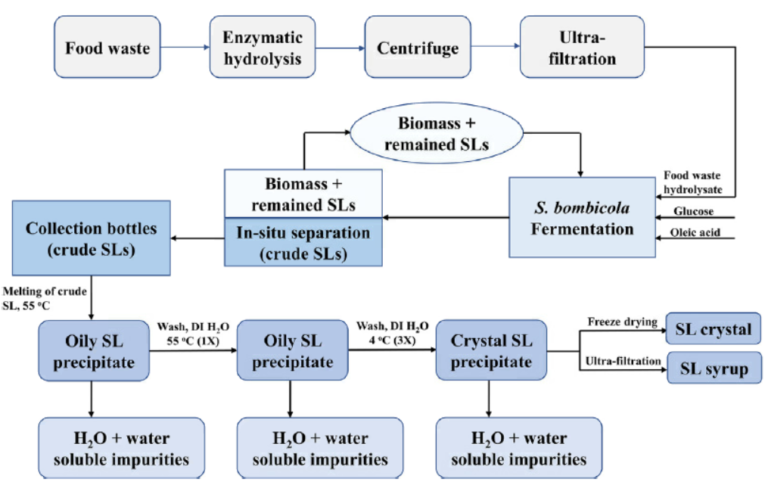

This study evaluates the techno-economic feasibility of sophorolipid (SL) production process that co-utilizes food waste, glucose and oleic acid as substrates. Two variables are considered in terms of (a) Plant construction: Purchasing equipment either from the US or Mainland China and (b) Production: to produce SL crystals or a concentrated SL liquid/syrup. Hence, four scenarios are generated: Scenario I: equipment made in the USA + SL crystals; Scenario II: equipment made in the USA + SL syrup; Scenario III: equipment made in China + SL crystals; Scenario IV: equipment made in China + SL syrup. It is found that all scenarios are economically feasible and Scenario I has the highest net profit. Scenario III has the highest internal rate of return, net present value and the shortest payback period at a 7% discount rate. Finally, comparison of food waste-related techno-economic studies was conducted.

If you want to read more on this study, click here.